Every stained glass installation has its own unique solution. The photo and “typical” detail shown here can provide good starting points for discovering an approach that is best suited for a specific project. Some variation on this detail is utilized in most of ASG’s projects.

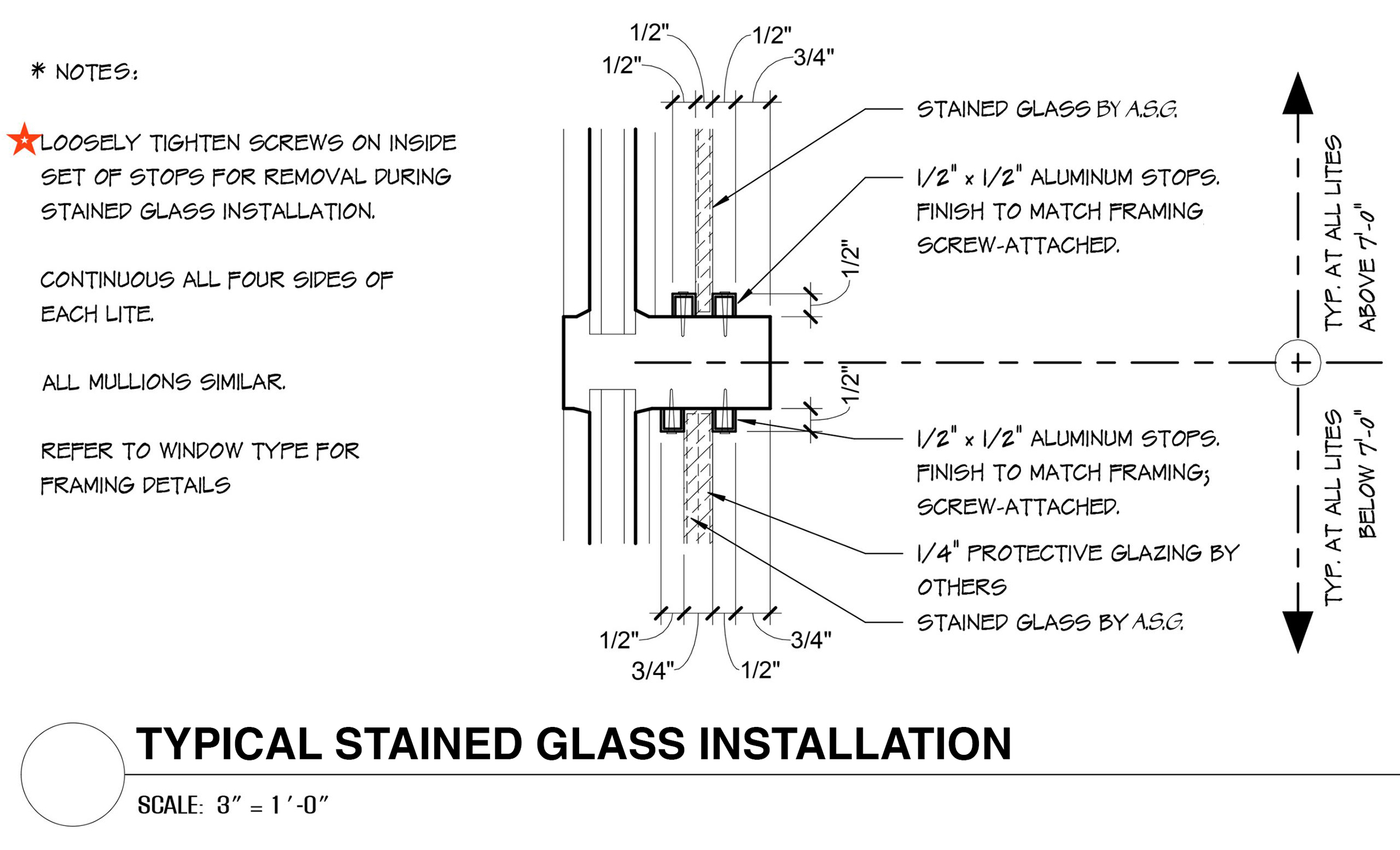

The thickness of a stained glass panel is approximately 5/16″. ASG typically suggests that the window framing system provide a 3/8” thick installation pocket to allow for glazing tape, shims and setting blocks. [NOTES: 1) For taller lites this pocket should be 1/2″ to accommodate horizontal saddle bars between stacked panels; 2) If protective glazing is required, the pocket-thickness will need to be increased accordingly.] See Anticipating Stained Glass: “Stop It!” for a more in-depth look or give us a call.

With aluminum framing systems, this pocket can easily be created with the addition of two sets of stops (sashes) to the basic window framing. These stops should be aluminum U-channel or square tube ranging from 1/2 x 1/2” to 3/4″ x 3/4”. Specifying stops in window framing details from the start assures a precise factory fit and color match between stops and framing. Including stops as part of the original window framing can also realize savings of up to 90% of the cost of their on-site retrofit into the windows at a later date.

Most of ASG’s installations rely on a version of this “typical” detail (click to enlarge):